We are aware of the importance of comprehensive range of services. It would be extremely inconvenient to transport materials from place to place in order to complete an order. This is why, in addition to laser cutting and press bending, we also offer:

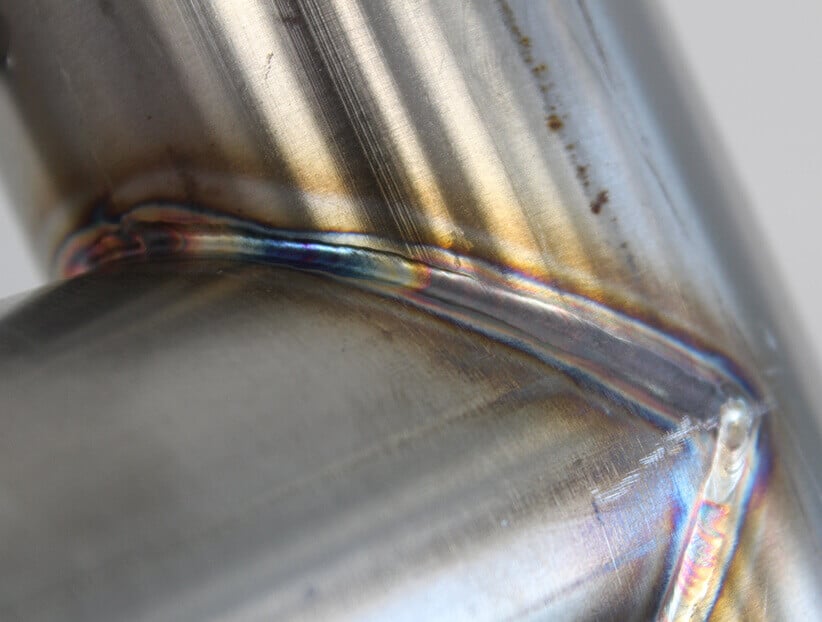

- TIG/MIG welding

- Galvanisation

- Powder coating

- Machining